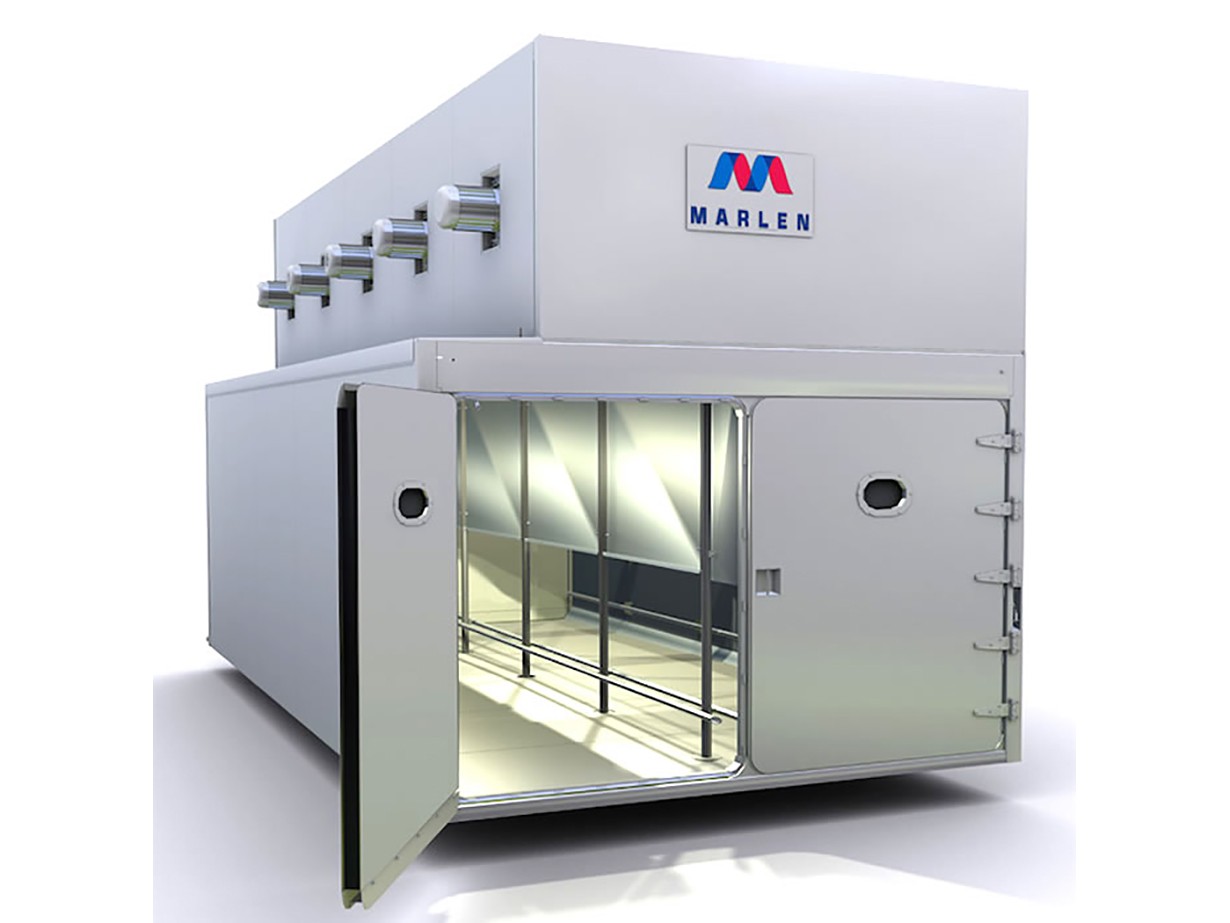

Batch Ovens, Smokehouses, Chillers & Industrial Dehydrators

Marlen food processing equipment uses the most current technology and innovation to provide workable solutions for your cooking and chilling needs. Marlen batch thermal processing solutions include custom designed industrial smokehouses, food processing batch ovens and cookers as well as industrial dehydrators.

Food Processing Oven & Industrial Smokehouse

.jpg)

Custom designed around your product, process and facility, our food processing ovens, cookers, and industrial smokehouses provide a more uniform product with smart balance precision for process repeatability day after day. With full control of the "breakpoint", weight, appearance, and internal temperature are maintained which is essential for repeatable processing and quality, uniform product. Visit our Riverside facility for a virtual reality tour of a Marlen batch oven (industrial smokehouse) to get a better

https://vimeo.com/79138047?embedded=true&source=vimeo_logo&owner=22595589

Features

- Smart Balance design uses fans, ducts and dampers, all working together to deliver the uniformity and efficiency no other thermal system can match. The Smart Balance design also uses 45° wall-to-floor deflectors to help enhance airflow. Permanent air balance ensures that your oven remains balanced, resulting in repeatable and consistent processing conditions day after day.

- Permanent factory air balancing of both supply and return air, ensure repeatable and consistent results

- Direct drive rotating dampers with innovative damper brake assembly to ensure critical breakpoint creates repeatable and consistent processing conditions

- Every design element is aimed at producing repeatable and consistent results in terms of temperature, color and yield

- Complete process verification through Powis-6000 Control system that verifies each cooking step, validates all changes, and provides complete HACCP data reporting after the process

- Energy efficient and simple design reduces horsepower requirements

- Single-inlet backward-inclined fan uses less horsepower to achieve required airflow for uniform cooking

- Innovative direct drive damper design replaces unreliable chain drive systems

- Pitched roof allows drainage from center to sides

- Hinged supply ducts allow for safe and easy access

- Wall skins are welded to internal frame to minimize wall distortion for superior durability

- Patented monolithic floor design eliminates typical recessed floors, eliminating a major harborage area

- Easy access to the psychrometer pan assembly, either from inside the oven or from on top of the oven

- Recessed door handles, inflation switches and flow meter for protection

- Simple design, allows easy access to serviceable areas, even while processing

- Marlen’s Safety-First emphasis is designed and built into every product

- Marlen International also offers Marlen parts for our Food Processing Ovens, Cookers, and Industrial Smokehouses

- Made in the USA

Industrial Dehydrator

Custom designed around your product, process and facility. Our industrial dehydrator provides a more uniform product, precise and repeatable results, complete data reporting, and easy access to serviceable areas. Visit our Riverside facility for a virtual reality tour of a Marlen deyhdrator to get a better understanding of our innovative design features and the Marlen advantage.

https://vimeo.com/79139897?embedded=true&source=vimeo_logo&owner=22595589

Features

- Smart Balance design uses fans, ducts and dampers, all working together to deliver the uniformity and efficiency no other thermal system can match. The Smart Balance design also uses 45° wall-to-floor deflectors to help enhance airflow. Increased air velocity over the surface of the product results in more uniform process conditions, day after day

- Permanent factory air balancing of both supply and return air, ensures repeatable and consistent results

- Innovative design keeps air in the “processing” zone for better performance.

- Rapid moisture removal promotes faster drying cycles

- Direct drive rotating dampers, with an innovative damper brake assembly to ensure that the critical breakpoint creates repeatable and consistent processing conditions

- Every design element is aimed at producing repeatable and consistent results in terms of temperature, color and yield.

- Custom designed around your product, your process, and your facility.

- Complete process verification through Powis-6000 Control system that verifies each cooking step, validates all changes, and provides complete HACCP data reporting after the process

- Energy efficient and simple design reduces horsepower requirements

- Single-inlet backward-inclined fan uses less horsepower to achieve required airflow for uniform cooking

- Innovative direct drive damper design replaces unreliable chain drive systems

- Robust contruction, easy to maintain

- Pitched roof allows drainage from center to sides

- Hinged supply ducts allow for safe and easy access

- Wall skins are welded to internal frame to minimize wall distortion for superior durability

- Patented monolithic floor design minimizes harborage areas.

- Easy access to the psychrometer pan assembly, either from inside the dehydrator or from on top of the dehydrator

- Recessed door handles, inflation switches and flow meter for protection

- Simple design, allows easy access to serviceable areas, even while processing

- Marlen’s Safety-First emphasis is designed and built into every product

- Marlen also offers Marlen parts for our Dehydrators

- World-class training

- Made in the USA

Blast Chill Cell

Our chillers feature a continuous chill process, allowing maximum heat reduction at a uniform rate, resulting in faster chill times, higher yields, and greater product uniformity while achieving maximum energy savings. Custom chilling recipes allow the product to aspirate naturally, giving up a precise amount of moisture and no more. This recipe not only brings about rapid stabilization but does so with optimum uniformity -- no "hot spots", no errant crusting.

Features

- Variable speed fans allow you to chill product faster using brine chill cabinets with more uniformity and in a sanitary environment

- Marlen’s variable speed fans run at low speed during “wet coil” conditions. Then, as desired moisture removal is nearly complete, fan speed increases and the system shifts to a lower temperature “dry coil” condition. This design significantly reduces shrinkage and prevents errant crusting.

- The Marlen chill cell control system stores and controls chilling “recipes,” logs processes and product temperature data for HACCP verification. This makes the system efficient by producing repeatable and uniform results allowing for higher yields.

- Exacting control for consistent high-yielding quality throughout the load, batch after batch

- Every design element is aimed at producing product that is uniform in terms of temperature, color and yield

- Optimized evaporator coil allows for faster chilling at higher refrigerant temperatures allowing you to save money in refrigeration cost

- Marlen continuous chill process is designed and constructed to maximize uptime through easy operation and maintenance

- Insulated, all welded stainless steel construction with built in CIP system

- Insulated Drain Pan Under Coil

- Marlen’s Safety-First emphasis is designed and built into every product

- Service-friendly design with logical and easy access to essential areas

- Marlen International also offers Marlen parts for the Blast Chillers and continuous chill processes

- Made in the USA

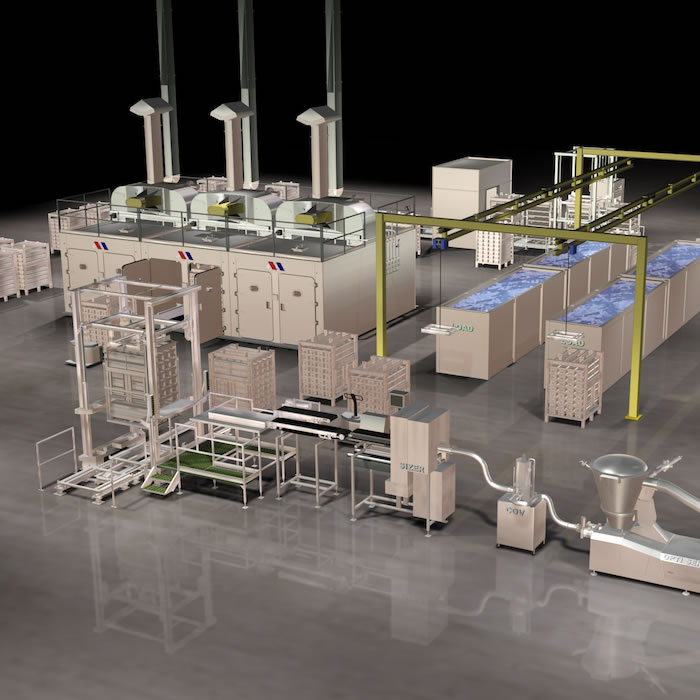

Automated Mold System

An efficient, ergonomically advanced forming system designed for molding product. It consistently forms product end-to-end.

Features

- Improve slicing yield by 5% or higher over end fill mold type systems

- Improve thru-put with faster load and unload time and fewer employees

- Molded Product decreases casing variations thus improving product uniformity

- Custom Designed around your product, process and facility

- Designed and constructed to maximize uptime through easy operation and maintenance with less labor

- Top loading mold is easier to load/unload

- No lids to handle; Mold lids are built into the rack

- No spring loaded lid to compress; Springs are permanent in rack

- Product can be stuffed in casing and held for molding at any time

- Product is stuffed at higher rate thus, reducing labor hours as stuffing rate increases/hr

- Made in the USA

Unload station – standard features:

- Two molds can be unloaded simultaneously

- Vacuum cups “grip” product for removal

- Compressed air lifts product from the molds

- Manual operation molds slide in and out-No lifting of molds!

- Take-away conveyor transfers molded product

- Complete with vacuum pump system

Load station – standard features:

- Control operation using electric push buttons

- Ergonomic design for loading molds into rack

- System raises and lowers rack for loading each level thus eliminating lifting the molds

- Hydraulic operation

- Epoxy coated hydraulic power unit

Press rack – standard features:

- Springs provide uniform pressure to all levels

- Custom designed to fit within existing cooking equipment

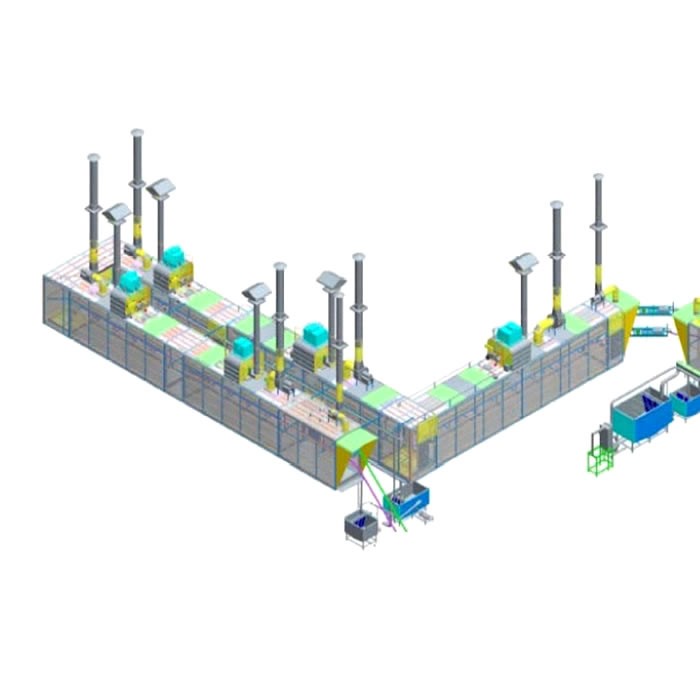

Monorail

Designed to optimize product flexibility with production rates ranging between 5,000 to 20,000 lbs per hour.

Features

- Permanent Air Balance reduces temperature, shrinkage and color variation in the oven

- Robust construction makes it easy to maintain

- Air handling equipment design reduces utility consumption

- Direct drive rotating dampers, with a patented “damper brake” assembly, ensure that the critical breakpoint creates repeatable and consistent processing conditions.

- Every design element is aimed at producing repeatable and consistent results in terms of temperature, color and yield.

- Air handling equipment design reduces utility consumption

- Multiple zones for maximum process flexibility in a continuous process system

- Made in the USA