Poultry processing

Food Mate

The Foodmate FM 7.50 breast cap deboning machine debones up to 3,000 breast caps per hour. The machine produces single, as well as butterfly fillets and features an automatic skinning and blister remover device. The breast cap deboner is easy to operate and can be loaded manually by one to two workers. Its design allows for adding a transport belt under the machine.

The MAXIMA 2.0 highlights the latest technology in breast meat deboning. This new Breast Cap Deboner is able to debone up to 3,000 breast caps per hour and produces single fillets. Final product is very well suited for tray-packing, requiring minimum trim as well as displaying perfect presentation. The machine offers a solution for deboning single fillets in an extremely simple and easy way, resulting in the highest possible yield and excellent product presentation. The Foodmate MAXIMA Breast Cap Deboning provides maximum performance, maximum simplicity and maximum flexibility, while requiring minimum floor space, as well as minimum maintenance and operating costs.

Capitalizing on its flexibility, the MAXIMA 2.0 can easily adjust to multiple plants’ set up and configurations requirements. The standard configuration includes a breast deboning unit for single breast fillets, a carcass unloader and an inline deskinning unit. In addition, the machine can be equipped with multiple conveyor belts, as it was designed to accommodate any conveyor belt direction variation.

New equipment is the automatic wishbone remover. The wishbone remover (AWR) automatically harvests the entire wishbone with minimum weight loss. The unit is extremely easy to adjust and maintain.

https://www.youtube.com/watch?v=-1MGoMUOkF8

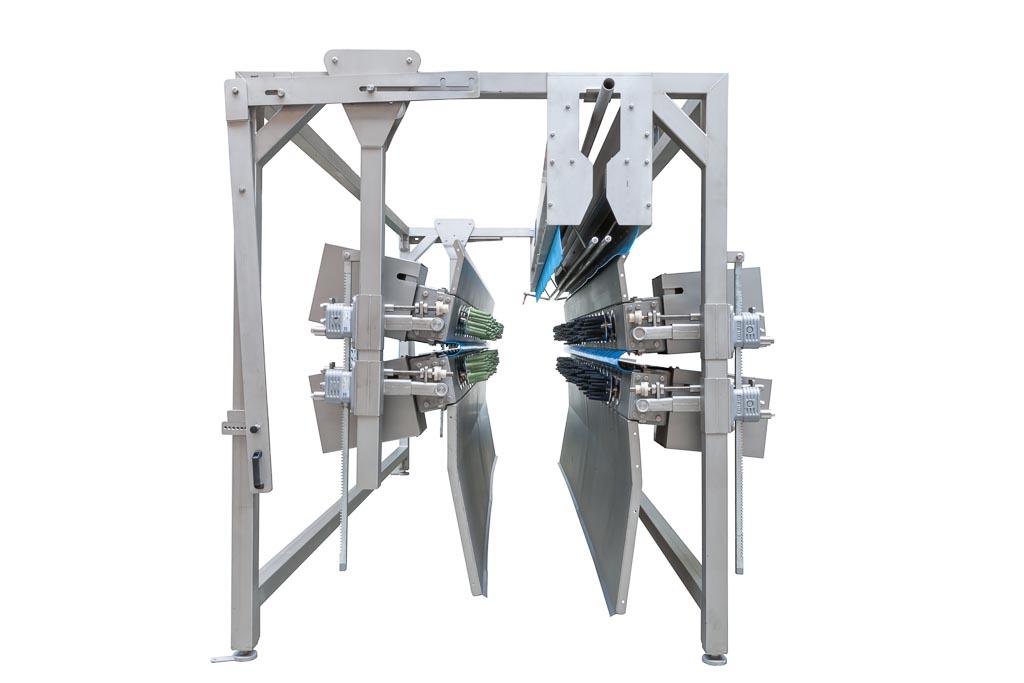

Working method:

- Two operators loads the special designed cone manually with breast caps.

- When the breast cap is placed on the cone, a special device automatically locks the breast cap

on to the cone.

- This is to ensure a stable position of the breast cap and to avoid the breast cap being

discharged before deboning.

- After locking, the cone turns automatically into position for deskinning.

- The breast cap deskinning starts from the tip towards the neck.

- After deskinning the cones turns automatically back into position for deboning.

- When entering the deboning unit, the breast caps will be automatically deboned. This process

is fully mechanical.

- After deboning the single fillets are automatically discharged.

- The remaining carcass will be automatically discharged by a static unloader.

- The empty cone turns into the 1st loading position.

Standard Configuration:

- Pre-cutter

- De-skinner

- Breast splitter/deboner

- NEW!!: Automatic wishbone remover

- Carcass unloader

Optional Equipment:

- Transports conveyor belt for breast caps with spreading unit

- Transport conveyor belt for waste products, like skins and carcasses

- Foodmate can supply the entire logistic system for infeed and outfeed

- Trimming conveyor belt for end product

Key Benefits:

- Unique compact design

- Low maintenance and operating cost

- Frequency converter

- Exceptional yield results

- Extremely stable and simple

- “Slow Run” position for cleaning

- Safety covers according CE-specifications

- Emergency stops according CE-specifications

Remarks:

- The wings should be removed from breast manual or by wingcutter

- Temperature of the product approx 4 °C

- Best deboning and yield result, when fresh products stay 1 night in the cooling

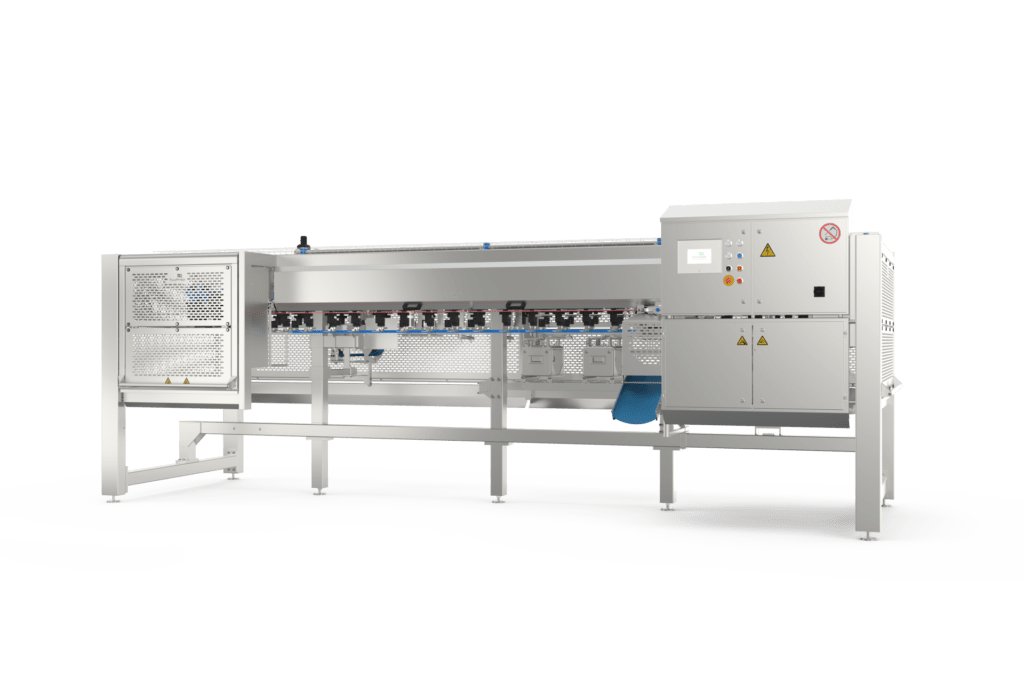

The Foodmate FM 7.50 breast cap deboning machine debones up to 3,000 breast caps per hour. The machine produces single, as well as butterfly fillets and features an automatic skinning and blister remover device. The breast cap deboner is easy to operate and can be loaded manually by one to two workers. Its design allows for adding a transport belt under the machine.

The FM 7.50 requires minimal floor space and is easily moved. Constructed with stainless steel and food approved nylons for hygiene, Foodmate has taken the additional steps of equipping the FM 7.50 with stainless steel wash down motors.

Key Benefit:

- Allows for a maximum of 3,000 birds per hour.

- Stainless steel and food approved nylon constructed breast deboner for whole filets (butterfly)

or ½ fillets.

- Raised construction for installation of a belt conveyor underneath the machine.

- Machine is suitable for breasts with out back bone, with or without skin.

- Including deskinning unit, blister remover and precut device.

Remarks:

- The wings should be removed from breast manual or by wingcutter

- Temperature of the product approx 4 °C

- Best deboning and yield result, when fresh products stay 1 night in the cooling.

https://www.youtube.com/watch?list=PLuZN06P3cFFHSuntXNR-0WECNXO5Fa9nX&v=qXTluhSCe8Q

.jpg)