Poultry processing

Food Mate

You are here: Home > Product Guide > Poultry Processing > Weighing Systems > WTS Weigh Transfer System

WTS Weigh Transfer System

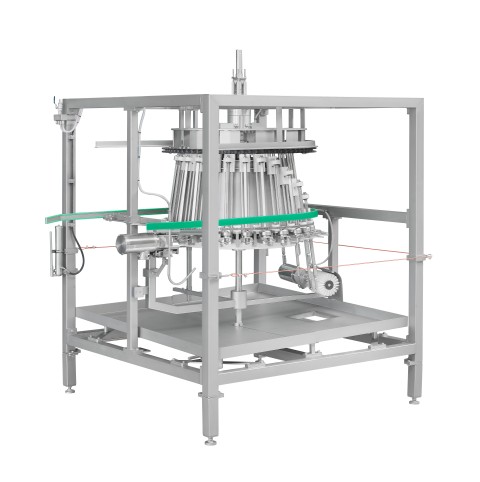

Designed by Foodmate in collaboration with ChickSort®UK, the WTS Weigh Transfer System boasts speeds in excess of 12000 bph and performs weighing accuracy of ± 10 gram. This new weigh transfer machine offers both speed and accuracy in a simple and compact solution.

Fundamental to the design is a simple but effective transfer mechanism that is easy to set-up and maintain. In addition, the WTS displays a triple load cell weigh head arrangement, which maximizes the weighing time of each bird. Because the weigh heads are stationery, they can be mounted on a separate tower to avoid low frequency vibration from the machine adversely affecting the weighing. Compared to weigh transfer systems from other suppliers, this solution maximizes the weighing “window” without over complicating the design with revolving electronics, slip rings etc.

The design also avoids the problems associated with existing singlehead and multi-head weighing machines where the loss of one weigh head has a catastrophic effect on production, requiring immediate machine maintenance and down-time. In the unlikely event of a weigh head being lost on this machine, the result is reduced weighing accuracy rather than birds not being weighed at all. Furthermore, as each weigh head is used to measure the weight of every bird, advanced diagnostics allow the automatic detection of weighing problems before they have a negative effect on production.

Key benefits:

- Speeds in excess of 12000 bph and performs weighing accuracy of ± 10 gram

- Easy set up

- Simple and compact design

- Effective and reliable transfer mechanism

- Automatic detection of weighing problems before they have a negative effect on production

- User friendly

- Easy to maintain and operate

The Foodmate Cropping Machine is a stainless steel constructed, automatic crop remover. Each unit is fitted with a special cropping head, which passes through the bird. The units are chain driven by a separate motor and cropper heads are cleaned by a rotating motor-driven brush. The machine is driven by the overhead conveyor.

Key Benefit:

- Allows for a maximum of 9,000 birds per hour

Technical Specifications

- Stainless steel frame and motor

- Motor (IP66) power is 0,75 kW,

1500 rpm

- Units: 16 or 24

- Pitch: 6" or 8"

- Rotation: CW/CCW

- Conveyor type:

- Pipe

- T-track

- Machine dimensions:

- Length: 2195 mm (units 16)

2590 mm (units 24)

- Width: 1600 mm (units 16)

2000 mm (units 24)

- Height: 2840 mm

- Weight: approx. 850 kg (units 16)

approx. 1200 kg (units 24)

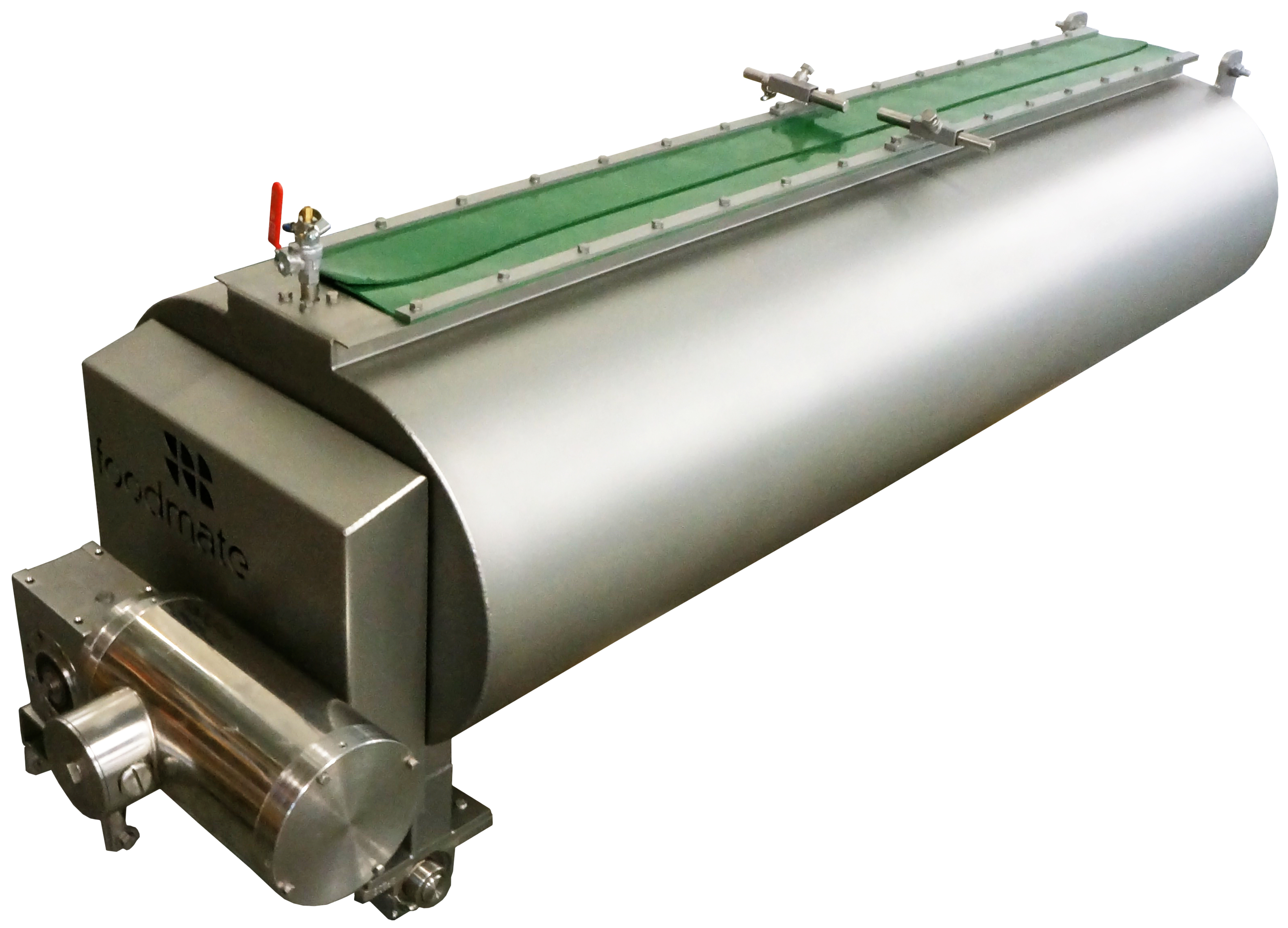

The Foodmate Automatic Bird Washer is a stainless steel constructed, automatic, inside and outside bird washer. Each unit contains a special spray nozzle. The machine is height adjustable for various bird sizes and driven by the overhead conveyor.

Key Benefit:

- Allows for a maximum of 9,000 birds per hour.

Technical Specifications

- Stainless steel frame

- Units: 16

- Pitch: 6" or 8"

- Rotation: CW/CCW

- Conveyor type:

- Pipe

- T-track

- Machine dimensions:

- Length: 2676 mm

- Width: 1600 mm

- Height: 2649 mm

- Weight: approx. 650 kg

Automatic chain/trolley and shackle washer washes by means of the rotating brushing principle. Shackles pass through the machine while rotating brushes and water clean the shackle before starting a new cycle. The washer is situated as the last unit in the line before hanging or transfer.

The washer is installed in a 45 degrees angle and is suitable for high speed lines.

Stainless steel opposing cabinets contain the motor driven hard brushes, which clean trolleys, chain and shackles over a 1.600 mm distance from top to bottom.

Key Benefit:

- Brush length: 1.600 mm

Stainless steel frame and motor

- Machine dimensions:

- Length: 1946 mm

- Width: 564 mm

- Height: 393 mm