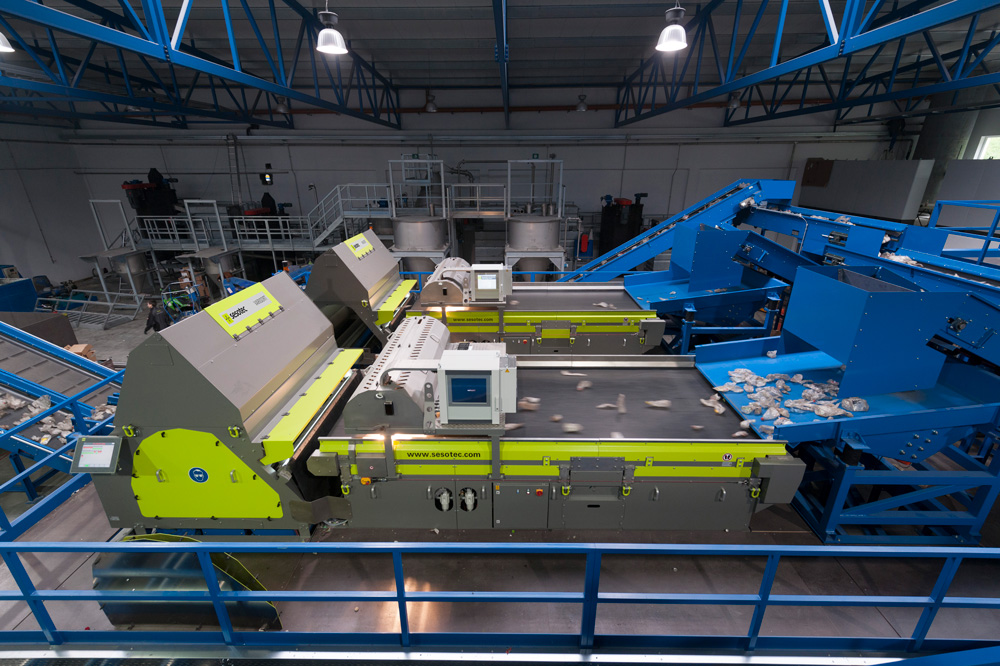

glass, scrap metal and electrical waste. The modular design makes it possible to custom combine various sensors.

Recycling sorting systems with conveyor belt are suitable for sorting mixed, piece or shredded materials. Sesotec offers machinery designed specifically for one purpose as well as universal multi-sensor systems that are able to process different types of material. Our multi-sensor sorting systems divide mixed material flows into uniform fractions and thereby help to profitably introduce recycled materials back into the production cycle. Different sensors can be used for this purpose, depending on the application: colour and shape sensors, metal sensors or near-infrared sensors (please refer to the different versions and configurations as well).

More information on how Sesotec recycling sorting systems with conveyor belt work is available.

That's what distinguishes our products

Easy to use

Highest detection accuracy

Easy cleaning and maintenance

Easy installation

The benefits of our conveyor belt sorting systems in detail

- Our sorting systems can be used flexibly and universally

- They guarantee the safe detection and removal of contaminants

- They have a high throughput capacity thanks to configurable belt speeds

- The modular design of Sesotec’s sorting systems makes it possible to combine up to three sensors for detecting contaminants: a colour and shape sensor, a metal sensor and a near-infrared sensor that distinguishes between different types of material

- A touch display with intuitive navigation makes it possible to operate and configure our systems quickly and easily

- The smart operating software SesoDesk with Octa-Core technology enables parallel signal processing of sensor information while guaranteeing the greatest degree of flexibility, even when it comes to challenging sorting jobs

- It is possible to retrofit sensors without any hassle

- Our sorting systems are adapted to the individual area of application, designed for durability thanks to wear protection and are easy to maintain

- The energy-efficient Sesotec systems have been optimised with regard to the consumption of compressed air and electricity

Product example VARISORT+

Alternative system configurations for a wide range of applications

Multi-sensor sorting systems VARISORT for various recycling applications

divide mixed material flows into uniform fractions. The material (e.g. PET bottles, electrical waste, scrap metal and household waste) reaches the detection area optimally scattered by way of a fast-moving conveyor belt. Once there, sensors “scan” the material flow based on colour, shape and type of material. A metal sensor detects metals, with optional detection of stainless steels as well. The electronic analysis assembly then activates the air ejection unit with exact timing and positioning, which removes the contaminants from the material flow.

Conveyor belt sorting systems K9 for recycling glass

separate glass fragments by colour and effectively remove foreign material, such as ceramic, stones and porcelain (CSP), with reliability. They are also able to achieve high-quality single-colour fractions out of mixed-colour glass fragments, as well as detect and remove heat-resistant or special leaded glass.